Polymer memory

What is polymer memory?

Polymer memory refers to memory technologies based on the application of organic polymers. Some of these technologies use variations in the resistance of carrying polymers under reading/write command. Different architectures are based on ferroelectric polymers. The characteristics of polymer memory are low-cost and high-performance and have the potential for 3D stacking and mechanical adaptability. Alternatives can be write-once or multiple-write. Printed versions of this technology previously exist and are applied in low-density applications such as toys.

PEDOT (polyethene dioxythiophene)

A polymer known as (PEDOT) is a vital plastic since it carries electricity at low voltage, which creates this polymer fit for anti-static coating in several industrial processes. Later, it was discovered that at the high pulse of current shifts it into the non-conducting state (acts as an insulator). The PEDOT based memory was used to store the digital data as zeros and ones. By accumulating layers of mind, a cubic centimetre device could hold as much as a gigabyte and be adequately modest to rival CDs and DVDs.

PRESENT MEMORY TECHNOLOGY Synopsis

Digital Memory is and has been a familiar comrade of each technological improvement in Information Technology. The current memory technologies have several limitations. DRAM is unstable and disturbing to integrate. RAM is a considerable price and explosive. Flash has slower writes, and a minor number of write/erase cycles related to others. These memory technologies, when required to expand, will support expansion in only two-dimensional space. Hence the area needed will be increased. They will not permit stacking of one memory chip over another. Also, the storage spaces are not enough to fulfil the exponentially growing requirement. Hence industry is searching for “Holy Grail” expected memory technologies for portable gadgets such as cell phones, mobile PCs etc. Next-generation thoughts are trying a tradeoff between size and price. This makes them good possibilities for improvement.

NEXT GENERATION MEMORIES

As stated earlier microchip makers proceed to wring more and more from silicon, a high number of memory technologies emerged. These memory technologies are related to ‘Next Generation Memories’. Next-Generation Memories provide all of the functional attributes of memory. The most prominent one among them is their ability to maintain expansion in three-dimensional spaces. Intel is the most prominent inventor of computer processors. Also, the largest maker of flash-memory chips is seeking to link the processing features and space requirements function, and various next-generation memories are being analyzed in this aspect. They involve MRAM, FeRAM, Polymer Memory and Ovonics Unified Memory.

Polymer memory is the best technology among them. It is mainly because of their expansion ability in three-dimensional spaces.

How does Polymer Memory work?

Composing a digitalized memory device indicates finding a way to represent the ones and zeros of computer logic, devising a relatively accessible way to get these binary patterns from storage, and producing sure the information prevails continuously. Polymer memory reserves information in an entirely distinct way than silicon devices. Preferably than encoding zeroes and ones as the number of the charge stored in a cell, Coatue’s chips collect data based on the polymer’s electrical resistance. Proceed

assembles each memory cell as a polymer sandwiched among two electrodes. To initiate this cell structure, a voltage is employed between the tip and bottom electrodes, transforming the organic matter. Various voltage polarities are done to write and read the cells.

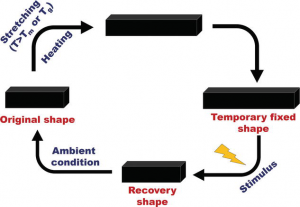

What is a shape memory polymer?

Shape memory polymers are polymer elements that you can disfigure and then by applying a stimulus, such as heat or light, will return to its previous form.

A shape memory polymer can replace an irregular form that is achieved by deforming it, to a previous way which is its changeless shape when it is not being deformed.

Many stimuli can be used to achieve this. So far this has been created using heat, light, irradiation with infrared light, immersion in water, and treatment of electric or magnetic fields.

Applications for shape memory polymers

There are an about infinite amount of potential applications for shape memory polymers. The ability to return to shape after several stimuli are involved allows a dynamic element to a product idea that could transform certain product varieties. There is already a list of applications in use in real-world perspectives, and the range of apps will likely continue to increase.

Some innovative possibilities involve smart textiles, self-deployable sun sails in capsules, intelligent medical tools and self-disassembling mobile phones.

Clothes and other ‘smart’ textiles

Because shape memory polymers can react to temperature, light, pH and moisture, there are several exciting possibilities for these elements in fabrics. These include relaxation, aesthetics, wound monitoring, security against environmental conditions, quick controlled drug relief, and more.

Features of Polymer Memory

- Zero transistors for each bit of storage.

- The Memory is Nonvolatile.

- Microsecond first reads. Its writing speed is faster than NAND and NOR Flash.

- First preparing, simple to organize with many CMOS.

- No cell backup control or refresh required.

- It operates temperature ranges between – 40 and 110°C.

Benefits of Polymer memory

- Plastic memory is responsive. Lab modelled devices with a 1GB storage limit have allowed read/write process durations that are many times (10 times) faster than CompactFlash, which are usually 10MB/s read, 1-4MB/s compose, thus giving quick read and write rate.

- Low energy utilization.

- It needs far fewer transistors, usually 0.5M (million) for 1GB of storage space contrasted with silicon’s 1.5-6.5B (billion).

- It can be accumulated vertically in an item, yielding 3D space utilization silicon chips must be set next to one another.

- Simple to fabricate use ink-jet printers to shower fluid polymer circuits on a surface

- The tiny Film framework needs about 0.5 million transistors for every gigabyte of memory. The traditional silicon-based structure would need between 1.5 to 6.5 billion transistors for that equivalent gigabyte.

Constraints of Polymer memory

- Becoming a polymer memory into a commercial memory is a tiresome task as the memory technologies struggle not only based on storage limit but also in energy consumption, rate and unwavering quality and so on.

- It can read multiple times but can write just one time.

- Until modern memory materials can dispute the high performance of silicon, their notes, they are seemingly going to be constrained to niche applications.

Read more about this